2020 Industry Fair: The Core Elements of Industrial Internet - Platform, Industrial Brain, Industrial Software and Application Practice

From September 15th to 19th, the 22nd China International Industrial Expo was held at the National Convention and Exhibition Center (Shanghai). This exhibition set up 9 new generation information technology and application exhibitions, robot exhibitions, industrial automation exhibitions, and scientific and technological innovation exhibitions. exhibition area. Among them, the New Generation Information Technology and Application Exhibition includes Haier Kaos, Inspur Cloud, China Mobile, China Unicom, Xuelang Digital System, Intelligent Cloud Technology, etc., all of which have booths. Regarding the details of the exhibition area, the Lei Feng Network Industry Group brought reports to industry professionals on site.

In the exhibition area, in addition to the original platform manufacturers constantly sinking their applications in various vertical industries and specific scenarios to expand the boundaries of empowerment, Leifeng.com found that telecom operators including China Mobile and China Unicom also exhibited their own The industrial Internet platform, the digital factory built by Black Lake Technology based on MES, and the factory brain of Xuelang Digital Systems were all unveiled at the exhibition.

1

Kaos and Inspur Cloud, two cross-platform applications are sinking

Haier Kaos IoT Ecological Technology Co., Ltd. (Kaos for short) is an industrial Internet "unicorn" independent from Haier Group. It ranked first among the "double-span" platforms selected by the Ministry of Industry and Information Technology in 2019.

On March 31 this year, Kaos completed a series A financing of up to 950 million yuan, breaking the XCMG Information Series A financing record of 300 million yuan. Then, on July 28, Kaos received another RMB 200 million A+ round of financing. Two consecutive rounds of billion-level financing have made it the “most profitable” company in the field of industrial Internet, and also provided strong support for their layout in the industrial Internet.

As the first batch of companies in China to explore the industrial Internet, they have begun to transform to intelligent manufacturing since 2012, striving to put themselves on the "crown" of the industrial Internet and transform from mass manufacturing to mass customization. Currently, the COSMOPlat platform is being applied in 15 vertical industries including home appliances, electronics, clothing, agriculture, chemicals, molds, machinery, RVs, ceramics, energy, education, food, general health, transportation, and smart cities.

In terms of supply chain industry ecology, Lei Feng.com learned from the booth staff that it is mainly aimed at import and export companies, or in the import and export link, looking for some overseas resources, etc., to provide these companies on the platform with a cross-border industry experience Overall solution. Realize online digital transformation through traditional offline operations.

For example, during the epidemic, Kaos was looking for medical protection resources such as masks, temperature guns, and protective clothing overseas to support the frontline fight against the epidemic. It was supply chain microenterprises that took the lead.

For example, when some companies have demand for fresh food, freight forwarding, and warehousing and logistics, they currently only cooperate with one or a few partners. But when it comes to online, as long as there is a demand, the entire sub-industry of Kaos All suppliers will connect with some corresponding resources, so the company's choice range will expand, and the company's business model can be optimized as a whole through the industrial Internet.

Their cultural and travel industry solutions rely on the COSMOPlat platform to empower the mass customization model across industries to the RV industry. By integrating connected factories, smart RVs, RV campsites and tourism ecology, they provide everything from smart RV customization to smart travel scenarios. Program customization.

As a “double-span” platform selected by the Ministry of Industry and Information Technology in 2019, what exhibits will Inspur Cloud bring this time?

That is Inspur Yunzhou Industrial Internet Platform 2.0, which was officially released in June this year, providing two core services: "Quality Code" and "Cloud ERP". The platform was formerly known as Inspur Cloud In-Cloud, but has now been renamed.

The quality code platform assigns codes to products to form "one code for one object, one code for one address", linking industrial data of all factors and life cycles of design, production, circulation and consumption, realizing shared manufacturing in the production process, and realizing shared manufacturing in the circulation link. Improve supply chain efficiency and achieve product traceability in the consumption process. In addition, the quality code also plays the role of data collection, providing a source of industrial big data, thereby providing enterprises with full-industry chain collaboration and full-value scenario applications for digital marketing and order traction. According to official data, Inspur Yunzhou Quality Code has currently accumulated 39 major categories and 268 subdivided industries.

As for cloud ERP, they divided the exhibition area into three major sections: intelligent manufacturing cloud, GS Cloud and smart enterprise. Among them, Lei Feng.com learned that they started from the "intelligent platform" which is the "cloud + digital" industrial Internet platform, the "intelligent technology" includes AI Model, AR/VR and Edge, and the supply chain production of "intelligent kits" , manufacturing operations MOM, and "smart services" to create smart enterprises through changes in production methods, transformation of business models, and reshaping of industrial organizations.

2

Industrial Internet platforms of China Mobile and China Unicom

If we say the “most unexpected discovery” in this exhibition according to Lei Feng.com, it is that China Mobile exhibited in advance the “China Mobile Industrial Internet Platform” that has not yet been officially released to the public.

From the staff at the booth, Lei Feng.com learned that China Mobile’s industrial product system can be summarized as “1+1+1+N”. The first three “1”s refer to terminals, networks, and platforms respectively (i.e.: China Mobile Industrial Internet), and "N" refers to the N vertical fields it targets, including factories, steel, mines, power grids, chemicals, and regional industrial clouds.

Yue Jiang from China Mobile Shanghai Research Institute said:

"China Mobile is transforming, including the three telecom operators. Now we want to apply the technological achievements of 5G to the entire industry, not just at the consumer level. It used to be for mobile phones and was aimed at ordinary consumers. Now it’s To B, including companies in industry, transportation, energy and other industries. These are China Mobile’s in-depth layout.”

He also said that China Mobile Shanghai Research Institute is specifically responsible for the implementation of some of China Mobile's applications in various vertical industries. The research institute was established in 2018 and has been two years old. There are many mature cases. At the industrial level, connection services between OT and IT are the biggest advantage of China Mobile in the industrial Internet.

In addition, China Unicom also exhibited three industrial Internet platforms at this exhibition, respectively targeting cold chain management, equipment networking and energy management. China Unicom started working on the industrial Internet in 2017, and the industrial Internet platform was built from 2018 to 2019.

Talking about the specific functions of the cold chain management platform, the staff introduced that, for example, in the pharmaceutical industry, the entire pharmaceutical industry has regulatory requirements, including drugs, vaccines and blood. There are mandatory requirements for temperature during transportation, and it is There are legal provisions. He said:

"One is storage and the other is transportation. We have built a cold chain management platform for these two links to manage the entire storage and transportation links, as well as the entire temperature."

The main parameters of the cold chain logistics management platform include vehicle usage rate, cold chain equipment online rate, cold storage alarm rate, water tank alarm rate, as well as various alarm rankings, various abnormality proportions, etc.

3

Black Lake Technology: Building a digital factory based on MES

Founded in 2015, Black Lake Technology has developed a real-time collaboration system based on cloud algorithm models to provide manufacturing companies with data aggregation, real-time monitoring, analysis and interpretation, and intelligent decision-making. At this exhibition, they mainly exhibited digital factory and new manufacturing solutions.

The digital factory includes planning and scheduling, production execution, quality inspection, equipment maintenance, intelligent warehousing, and analysis and decision-making. With the help of self-built MES software, through real-time visual scheduling and real-time feedback of workshop information, chaos caused by order insertion can be dynamically adjusted; in addition, scanning the code for production + electronic SOP can be completed on the mobile phone, so there is no need to worry about missed operations or mistakes. Operations, and real-time reporting on mobile phones can prevent performance errors. In addition, in the smart warehousing process, you can scan the code to check production batches, usage processes, operators, operating specifications, raw material conditions, suppliers and customer conditions, etc., so as to optimize production.

4

Intelligent Cloud Technology: iSESOL platform and its industrial APP

As for Intelligent Cloud, the iSESOL industrial Internet platform provides cloud access services for smart equipment and manufacturing companies, and based on manufacturing process data, provides cloud platforms, one-stop industrial services, iSESOL application mall & developer center, iSESOL industrial APP, etc. Solutions and Applications.

The industrial platform-level intelligent hardware of iSESOL Industrial Internet is mainly designed to assist small and medium-sized enterprises with their needs for cloud migration, data collection, and equipment intelligence, etc. The iSESOL industrial APP mainly includes WIS intelligent cloud eyes, intelligent efficiency enhancement, tool monitoring, DNC, machine tool physical examination and other APPs.

Lei Feng.com also learned from the staff that WIS smart cloud eyes can be used for real-time collection, real-time penetration and real-time display of equipment operating data. Through real-time penetration of production data, problems can be discovered in a timely manner, ultimately improving efficiency, and after access When device data is synchronized with the cloud, no dedicated maintenance is required. The tool monitoring APP can collect machine tool tool load data in real time, generate the expected value of tool production status through data learning, monitor the tool status at any time during the production process, and remind you to change the tool when it is close to the expected value.

5

Xuelang Number System: Rebuilding the "Alibaba Cloud ET Industrial Brain"

The “factory brain” created by Xuelang Digital Systems provides industrial enterprises with cross-industry, cross-region and full life cycle data intelligence services. The company was founded in 2018. The founder Wang Feng is the founder of Alibaba Cloud ET Industrial Brain and the founder of Alibaba Cloud Digital Big Data Platform. Therefore, Xuelangyun's factory brain has more or less the shadow of Alibaba Cloud ET Industrial Brain. It focuses on construction machinery, large aircraft, chemical industry, steel/metallurgy and other industries.

Xuelangyun's factory brain is the PaaS platform, which is mainly composed of three tools: Hufu, Abacus and Hetu. Specifically refers to:

Hufu, an industrial data resource management platform;

Abacus, an industrial data intelligent APP development platform;

Hetu, an industrial data relationship graph analysis platform.

Hufu is actually a construction tool for the data center. It integrates and connects the data between ERP and MES systems to form a unified data system. Then on this basis, Abacus is for data application development, using graphical methods to quickly make some cross-system data applications, such as management and control, scheduling, etc., while Hetu is the precipitation of some mechanism rules, industrial AI tools and industries Mechanism Toolbox.

6

Chint: Empowering the thermoelectric industry with industrial Internet

How to use the industrial Internet to empower the process manufacturing thermoelectric industry? Lei Feng.com previously reported on Quanying Technology, namely "The Smog Is Coming, What Can the Industrial Internet Do?" 》

At this exhibition, Lei Feng.com discovered that CHINT has also launched a smart heating solution, which fully empowers the three ends of the thermoelectric industry: heat sources, heat exchange stations and users. It is mainly targeted at civil heating, industrial heating and commercial heating. Heating.

For example, heat sources, here is mainly the overall solution for heat source side electronic controllers launched for thermal power plants. According to staff member Han Ninggang, it can provide electronic control instrument solutions for various heat source types such as thermal power plants, steam boiler rooms, hot water boiler rooms, industrial waste heat, and geothermal water heating.

The equipment and control solutions of the heat exchange station can be understood as residential areas, providing full life cycle services such as heat exchange station design, production integrated supply, commissioning and operation, after-sales maintenance, etc., and the heat exchange station adopts frequency conversion and Combined throttling control makes the work process more stable. The filter adopts front and rear diameter reduction design to extend its service life.

When it comes to the user, that is, the building valve control system consists of a room temperature collector, household control valve, unit valve, wireless transmission channel, heating network comprehensive monitoring system, and heat exchange station control system. It can realize automatic room temperature collection, multiple control modes, Remote centralized control and heat exchange station realize linkage and other functions.

……

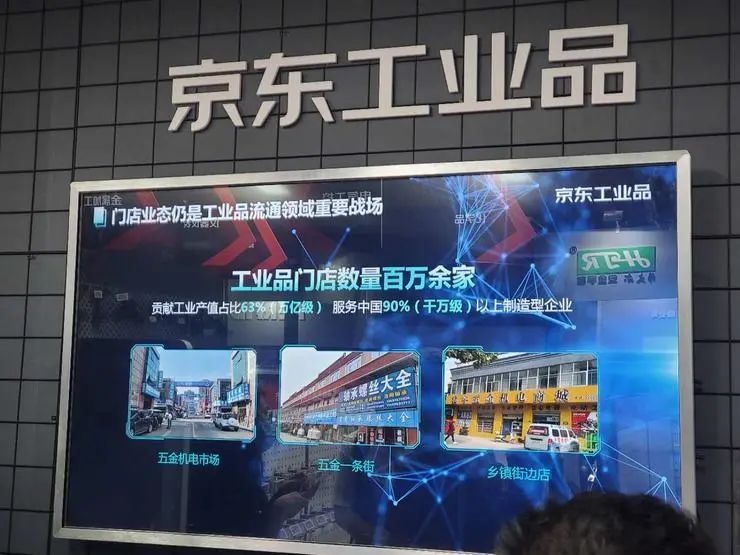

At the same time, "JD Industrial Products", a subsidiary of JD Group, also made its official debut. According to the group’s first quarter financial report, JD Industrial Products has signed a US$230 million Series A financing agreement, with a valuation of more than US$2 billion.

In addition, Lei Feng.com also paid attention to the industrial robot section of this exhibition. The German KUKA Group not only provides robot products, but also provides "digital + automation" solutions. Japan's FANUC's new-generation collaborative robot CRX-10iA also made its debut in China. The Swiss company ABB comprehensively presented future factories, future cars and future hospitals, and launched its new robot product IRB 1300 for the first time in the world. SIASUN, which has participated in the exhibition for many years, this year launched the "Fire Arc" robot intelligent welding system. The hollow bow-shaped arm reduces workpiece interference and can be seated or hoisted. It has high precision, high speed and high stability, and is capable of small turning radius and narrow areas. Operation.

As for parallel robots, compared with traditional industrial robots, its market is in an accelerated expansion stage. Wang Yuechao, Chairman of Bekent, said: "The Delta robot was invented in the 1980s, and its original design was to manipulate light and small objects at very high speeds. Therefore, the parallel robot has been endowed with high speed, high precision since its birth. genes. Compared with series robots, parallel robots have significant advantages such as high stiffness, stable structure, strong load-bearing capacity, and high precision."

Lei Feng.com learned that at this exhibition, 17 industrial and energy Internet projects were signed with a total investment of 6.88 billion yuan, and a number of industrial cooperation projects achieved new results. In the context of building a new "dual cycle" pattern, digital empowerment is used to expand new space for integrated development and synergy with the Yangtze River Delta manufacturing industry.